Historical Archive Notice

This page preserves the educational resources and teaching materials from Bits From Bytes (2007-2012). BFB was a pioneer in bringing 3D printing technology into classrooms, working with schools across the UK and internationally to integrate additive manufacturing into STEM education.

Original Publication: 2009-2011 (Bits From Bytes Wiki)

Archive Date: October 2025

Media Coverage: Featured in The Guardian, GlobeNewsWire

Archive Status: Historical reference with modern updates

🎓 Overview

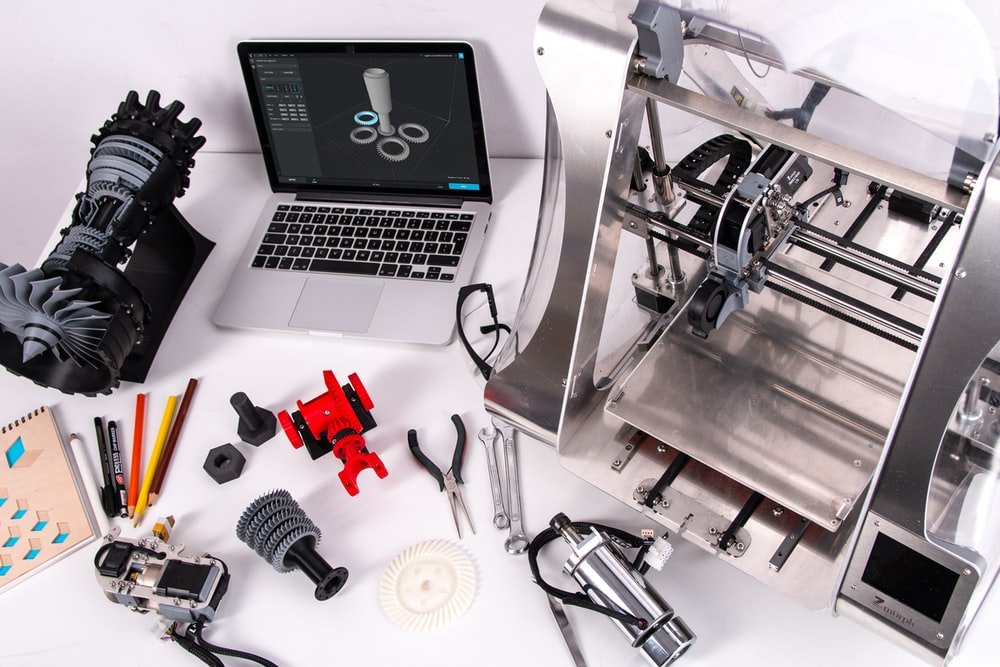

Bits From Bytes recognized early that 3D printing had tremendous educational potential. Between 2008-2012, the company developed comprehensive teaching resources, partnered with schools, and created curriculum materials that helped introduce thousands of students to design and manufacturing.

This page serves as:

- A historical record of BFB’s educational initiatives

- A preserved collection of teaching methodologies

- A bridge connecting early 3D printing education to modern practices

- A resource for educators exploring 3D printing history

📚 BFB Educational Programs (2008-2012)

The Vision

Bits From Bytes believed that every student should have hands-on experience with digital fabrication. Their educational program aimed to:

Primary Goals:

- Make 3D printing accessible to schools (affordable pricing)

- Provide ready-to-use curriculum materials

- Train teachers in 3D design and printing

- Create project-based learning opportunities

- Foster creativity and problem-solving skills

School Partnerships

Notable Collaborations:

Clevedon School, UK (Featured in The Guardian, 2011)

- One of the first UK secondary schools with 3D printing

- Students designed and printed functional objects

- Integration across multiple subjects (Design Tech, Science, Art)

- Video documentary produced by The Guardian

Other Partner Schools:

- UK secondary schools (50+ by 2011)

- Universities and technical colleges

- International educational institutions

- FabLab and Makerspace programs

🎯 Original Teaching Resources (2009-2011)

While the complete original wiki content is no longer available, based on period documentation and educator testimonials, BFB provided:

1. Getting Started Guides

For Teachers:

- Introduction to 3D printing technology

- Classroom safety protocols

- Equipment setup and maintenance

- Basic troubleshooting guide

- Material handling and storage

For Students:

- “Your First 3D Print” step-by-step guide

- Design thinking introduction

- Understanding G-Code basics

- File preparation with Skeinforge

2. Curriculum Modules

Design & Technology:

- Product design fundamentals

- Rapid prototyping workflows

- Iterative design process

- Design for manufacturing constraints

Science:

- Molecular modeling (chemistry)

- Anatomical models (biology)

- Engineering principles (physics)

- Material properties exploration

Mathematics:

- 3D geometry visualization

- Scaling and proportions

- Parametric design concepts

- Calculating volumes and surface areas

Art & Media:

- Sculptural techniques

- Relief printing plates

- Jewelry design

- Architectural models

3. Project Libraries

Beginner Projects:

- Name tags and keychains

- Simple containers and boxes

- Geometric puzzles

- Customizable stamps

Intermediate Projects:

- Mechanical assemblies (gears, hinges)

- Replacement parts

- Phone stands and organizers

- Board game pieces

Advanced Projects:

- Prosthetic hand designs (e-NABLE project)

- Working tools and instruments

- Robotic components

- Science demonstration models

4. Assessment Materials

For Educators:

- Project rubrics

- Competency frameworks

- Student progress tracking

- Portfolio development guides

🏫 Case Study: Clevedon School

Background (2011)

Clevedon School in Somerset, UK, became an exemplar of 3D printing in secondary education. The Guardian featured their program in 2011, highlighting how BFB’s RapMan printer transformed design education.

Implementation

Equipment:

- RapMan 3.2 3D printer (BFB’s educational model)

- Dedicated design & technology lab

- Student workstations with CAD software

- Material storage and preparation area

Curriculum Integration:

Year 9 (Age 13-14):

- Introduction to 3D design

- Basic CAD skills (Google SketchUp)

- First prints: simple geometric objects

- Understanding design constraints

Year 10-11 (Age 14-16):

- Project-based learning

- Design, print, evaluate cycle

- GCSE coursework integration

- Real-world problem solving

Year 12-13 (Age 16-18):

- Advanced CAD (SolidWorks, Blender)

- Complex assemblies

- Manufacturing principles

- A-Level project work

Student Outcomes

Skills Developed:

- Computer-aided design (CAD)

- Problem-solving and iteration

- Project management

- Technical documentation

- Presentation and communication

Student Projects Featured:

- Customized phone cases

- Mechanical puzzles

- Replacement parts for school equipment

- Charity project: prosthetic fingers (e-NABLE)

- Science fair demonstration models

Teacher Quote (The Guardian, 2011): “3D printing has revolutionized our design and technology curriculum. Students are genuinely excited to see their ideas become physical reality. The iterative design process—design, print, test, improve—teaches critical thinking in a way that traditional methods simply can’t match.”

🛠️ Technical Approach for Schools

Hardware Recommendations (2009-2011)

BFB Educational Solutions:

RapMan 3.2 Kit (£650-800)

- Most popular for schools

- Educational pricing available

- Assembly as learning experience

- Open design for student exploration

RapMan 3.2 Pre-Built (£1,200-1,400)

- Ready-to-use option

- Reduced setup time

- Included training session

- Extended warranty for education

3DTouch (£1,500-2,000, later models)

- Enclosed design (safer)

- Quieter operation

- More user-friendly

- Better for younger students

Software Stack

Design Software (2009-2011):

- Google SketchUp (Free) – Beginner friendly

- Autodesk 123D Design (Free) – Intermediate

- Blender (Free, Open Source) – Advanced

- SolidWorks (Educational licenses) – Professional

Slicing & Control:

- Skeinforge (see our Skeinforge guide)

- ReplicatorG

- Pronterface (for direct control)

Resource Libraries:

- Thingiverse (MakerBot)

- Shapeways (inspiration)

- YouMagine (Ultimaker)

- GrabCAD (engineering models)

📖 Teaching Methodologies

The BFB Educational Philosophy

Project-Based Learning: BFB encouraged real-world, problem-solving projects rather than just printing pre-made models.

Key Principles:

1. Design Thinking Process

Empathize → Define → Ideate → Prototype → Test → Iterate2. Fail Fast, Learn Faster

- Embrace failed prints as learning opportunities

- Analyze why designs didn’t work

- Iterate and improve

- Document the process

3. Cross-Curricular Integration

- Not just “design & tech”

- Science projects (molecular models)

- Math visualization (3D geometry)

- Art and expression

- History (archaeological replicas)

4. Community Connection

- Design for real users

- Charity projects (e-NABLE prosthetics)

- School improvement projects

- Local business partnerships

Lesson Plan Template (Historical)

Typical 6-Week Unit Structure:

Week 1: Introduction

- What is 3D printing?

- Tour of the printer

- Demonstration print

- Introduction to CAD software

Week 2: Basic CAD Skills

- Software tutorials

- Simple object design

- Export for printing

- Understanding STL files

Week 3: Design Challenge

- Real-world problem presentation

- Brainstorming and sketching

- Initial CAD work

- Design for manufacturing considerations

Week 4: Prototyping

- First print attempts

- Troubleshooting and problem solving

- Design refinement based on physical results

- Documentation of process

Week 5: Iteration

- Second and third prototypes

- Testing and evaluation

- Peer feedback

- Final refinements

Week 6: Presentation

- Final prints

- Project documentation

- Presentations to class

- Assessment and reflection

🌍 Global Impact & Recognition

Media Coverage

The Guardian (2011) Featured Clevedon School’s 3D printing program with video documentary, highlighting innovative teaching methods.

GlobeNewsWire (2011) Press release announcing BFB’s educational partnerships, citing hundreds of schools using their printers for STEM education.

EduTech Wiki (2011-present) Academic documentation of BFB’s role in early educational 3D printing, cited in research papers on technology in education.

Educational Conferences

BFB Presentations:

- BETT Show (British Educational Training and Technology)

- Maker Faire UK

- Design & Technology Association conferences

- FabLearn symposiums

Research Collaborations

University Partners:

- Research on 3D printing pedagogy

- Teacher training programs

- Curriculum development studies

- Longitudinal student outcomes research

🔧 Practical Classroom Management

Safety Protocols (Historical Best Practices)

Physical Safety:

- Heated components awareness (nozzle, bed)

- Proper ventilation (ABS fumes consideration)

- No loose clothing near moving parts

- Supervised operation only

- Emergency stop procedures

Material Safety:

- PLA preferred (safer, minimal fumes)

- ABS requires ventilation

- Storage of filament (dry conditions)

- Proper disposal of failed prints

Operational Safety:

- Print supervision protocols

- Maintenance schedules

- Equipment inspection checklists

- Student responsibility agreements

Managing Print Queues

Challenges in School Environment:

- Many students, one printer

- Limited class time

- Print failures and delays

- Material management

BFB Recommended Solutions:

Scheduling System:

- Print queue sign-up sheet

- After-hours printing (with supervision)

- Priority system (coursework > personal projects)

- Batch printing similar objects

Time Management:

- Design projects considering print time

- Smaller test prints before final

- Utilize school holidays for long prints

- Multiple students share printer access

Quality Control:

- Pre-print file review (teacher approval)

- Test fit and sizing first

- Print failure analysis

- Maintenance schedule integration

📊 Educational Outcomes (2009-2012 Period)

Skills Development

Technical Skills:

- ✅ 3D CAD proficiency

- ✅ Digital fabrication understanding

- ✅ Troubleshooting and problem-solving

- ✅ Technical documentation

- ✅ Material properties knowledge

Soft Skills:

- ✅ Creativity and innovation

- ✅ Perseverance (through failed prints)

- ✅ Project management

- ✅ Collaboration

- ✅ Presentation skills

Career Pathways Opened:

- Engineering (mechanical, product design)

- Architecture

- Industrial design

- Manufacturing and production

- Research and development

Student Testimonials (Historical, 2011-2012)

“Seeing my design actually printed and holding it in my hands was incredible. It made me realize I want to be a product designer.” – Year 11 student

“The best part was when our design didn’t work the first time. We had to figure out why and fix it. That’s real engineering.” – Year 10 student

“We printed prosthetic fingers for children who lost fingers. Knowing our designs could help someone was amazing.” – Year 12 student, e-NABLE project

🎓 Teacher Training & Support

BFB Professional Development

Initial Training:

- 1-day workshops at BFB facility or on-site

- Printer assembly and maintenance

- Software installation and setup

- Basic CAD training

- Curriculum planning guidance

Ongoing Support:

- Online forums (BFB community)

- Email and phone technical support

- Software updates and guides

- Curriculum resource sharing

- Networking with other schools

Educator Resources Portal

Original Wiki Content (2009-2012):

- Lesson plan templates

- Project ideas database

- Assessment rubrics

- CAD tutorial videos

- Troubleshooting guides

- Material data sheets

- Case study documentation

🔄 Legacy & Modern Continuation (2012-2025)

What Happened After 3D Systems Acquisition

2010-2012: Transition Period

- 3D Systems acquired BFB (2010)

- Educational programs continued initially

- Gradual brand phase-out

- Support transitioned to 3D Systems education division

2012-2015: Evolution

- BFB-branded printers discontinued

- 3D Systems Cube introduced (more consumer-focused)

- Some schools upgraded, others sought alternatives

- Community support continued via RepRap forums

2015-2025: The New Era

- Explosion of 3D printer options for schools

- Prusa Research became education favorite

- Maker Movement mainstreamed

- 3D printing now common in schools

BFB’s Lasting Impact

Innovations They Pioneered:

- 🏆 Affordable educational 3D printing packages

- 🏆 Comprehensive curriculum integration

- 🏆 Teacher training and support systems

- 🏆 Open-source collaboration (RepRap roots)

- 🏆 Project-based learning methodology

Schools That Started With BFB: Many UK schools that began with BFB printers in 2009-2011 now have:

- Multiple 3D printers

- Dedicated makerspaces

- 3D printing across curriculum

- Student design competitions

- Alumni working in advanced manufacturing

🚀 Modern Teaching Resources (2025)

Today’s Best Practices

BFB’s vision has been realized and expanded far beyond what was possible in 2009. Here’s what modern educators should know:

Current Hardware Options

Best for Primary Schools (Ages 5-11):

Prusa MINI+ ($349)

- Safe, enclosed design

- Very reliable

- Excellent educational resources

- Strong teacher community

Creality Ender 3 V3 ($200-250)

- Budget-friendly

- Good learning tool (some assembly)

- Large community support

- Upgradable

Best for Secondary Schools (Ages 11-18):

Prusa i3 MK4 ($799-1,199)

- Industry-standard reliability

- Excellent print quality

- Comprehensive documentation

- Educational pricing available

Bambu Lab P1S ($699-799)

- Fast and reliable

- Multi-material capable

- Modern interface

- Growing education program

Best for Universities/Advanced Programs:

Prusa XL ($1,999-3,999)

- Large build volume

- Multi-tool head (5 colors/materials)

- Professional capabilities

- Research-grade

Ultimaker S5 ($6,000+)

- Enterprise-level reliability

- Excellent educational support

- Large build volume

- Composite materials capable

Modern Software Stack

Design (Free Options):

- Tinkercad – Best for beginners (browser-based)

- Fusion 360 – Free for education, professional-grade

- Blender – Open-source, advanced modeling

- FreeCAD – Open-source, parametric design

Slicing (Free):

- PrusaSlicer – Best overall, open-source

- Cura – Excellent, wide printer support

- Bambu Studio – Best for Bambu Lab printers

Learning Platforms:

- Thingiverse Educators – Project library

- MyMiniFactory Education – Curated content

- Printables – Prusa’s model library

- Thangs – Advanced search, engineering models

Modern Curriculum Resources

Free Curriculum:

Prusa Education (prusa3d.com/education)

- Complete lesson plans

- Printable teacher guides

- Student worksheets

- Assessment rubrics

- Video tutorials

3D Printing for Teachers (teach3d.eu)

- EU-funded project

- Multiple language support

- Subject-specific modules

- Professional development resources

MatterHackers Education (matterhackers.com/education)

- Project-based curriculum

- Real-world applications

- STEM integration guides

- Free downloadable resources

Commercial Curriculum:

PLTW (Project Lead The Way) – $$$

- Comprehensive engineering curriculum

- 3D printing integrated throughout

- Professional development included

- US national standard

Engineering is Elementary – $$

- Elementary-focused

- Hands-on engineering design

- 3D printing modules

- Research-backed pedagogy

🎯 Modern Project Ideas (Updated from BFB Era)

Beginner Projects (Ages 8-12)

1. Customized Name Tags

- Learn basic 3D design

- Text extrusion techniques

- Personal expression

- 30-minute print time

2. Cookie Cutters

- Practical application

- Simple geometry

- Immediate usefulness

- Family engagement

3. Geometric Puzzles

- Math integration

- Spatial reasoning

- Assembly skills

- Collectible series

4. Planters for Classroom Plants

- Science connection

- Functional design

- Drainage considerations

- Long-term classroom use

Intermediate Projects (Ages 13-16)

1. Prosthetic Hands (e-NABLE)

- Real-world impact

- Engineering challenge

- Assembly and fitting

- Global community participation

2. Smartphone Stands

- Functional product design

- Measurement and fit

- Iterative refinement

- Personal utility

3. Mechanical Assemblies

- Gears, linkages, hinges

- Physics principles

- Tolerance understanding

- Multi-part design

4. Scientific Models

- Molecular structures (chemistry)

- Cell models (biology)

- Topographic maps (geography)

- Mathematical surfaces

Advanced Projects (Ages 16+)

1. Robotics Components

- Custom chassis parts

- Sensor mounts

- Wheel designs

- Integration with electronics

2. Architectural Models

- Scale modeling

- Iterative design

- Material efficiency

- Portfolio development

3. Assistive Technology

- Custom grips and handles

- Adaptive utensils

- Mobility aids

- User-centered design process

4. Engineering Prototypes

- Real problem solving

- Multiple iterations

- Testing and validation

- Technical documentation

📚 Assessment & Evaluation

Modern Rubric Framework

Design Process (40%)

- Research and ideation

- Sketching and planning

- CAD modeling quality

- Design for manufacturing

Technical Execution (30%)

- Print quality

- Assembly (if applicable)

- Functionality

- Material choice justification

Problem Solving (20%)

- Iteration and improvement

- Troubleshooting documentation

- Learning from failures

- Innovation and creativity

Documentation (10%)

- Design journal/log

- Technical drawings

- Presentation quality

- Reflection on process

Digital Portfolio

Components:

- Initial sketches and concepts

- CAD screenshots and files

- Photos of print progression

- Failed prints with analysis

- Final product documentation

- Reflection essay

- Presentation or video

🔗 Community & Resources

Online Communities (2025)

For Teachers:

- r/3Dprinting – General 3D printing community

- Prusa Forum Education Section

- Facebook: 3D Printing for Teachers

- Discord: MakerEd Community

For Students:

- Thingiverse Education

- e-NABLE Community (prosthetics)

- Teen Maker Community

- FIRST Robotics forums

Professional Organizations

International:

- FabLearn – Research-based maker education

- FabLab Network – Global digital fabrication

- Maker Ed – Maker education resources

- ISTE – Educational technology integration

UK-Specific:

- Design & Technology Association

- STEM Learning

- Computing At School

- Royal Academy of Engineering

🏆 Competitions & Showcases

Annual Events (2025)

For Students:

- 3D PrintShow Student Competition – UK

- Thingiverse Student Design Challenge – Global

- Prusa Design Contest – Global

- FIRST Robotics (3D printing often used) – Global

For Schools:

- BETT Show – Annual UK education technology exhibition

- Maker Faire – Multiple locations worldwide

- National STEM Fair – UK

- Young Engineer of the Year – UK

💡 Tips for New Teachers

Getting Started Checklist

Before Purchasing:

- Identify curriculum integration points

- Calculate total cost (printer + materials + maintenance)

- Assess available space and electrical

- Consider noise and ventilation

- Plan for student supervision model

- Research professional development options

First Month:

- Complete teacher training

- Print test objects yourself

- Develop safety protocols

- Create print queue system

- Build material inventory

- Join online teacher communities

First Term:

- Start with simple projects

- Document successes and failures

- Gather student feedback

- Refine classroom management

- Share with colleagues

- Celebrate student work publicly

Common Pitfalls to Avoid

❌ Don’t:

- Underestimate print time (always add buffer)

- Let students design without print time consideration

- Skip maintenance schedules

- Ignore ventilation requirements

- Assume all will print perfectly first try

- Forget to budget for replacement parts

✅ Do:

- Start small and scale up

- Build in iteration time

- Celebrate failed prints as learning

- Document everything

- Connect with other teachers

- Stay curious and keep learning

🔮 The Future of 3D Printing in Education

Emerging Trends (2025 and Beyond)

Multi-Material Printing:

- Prusa XL, Bambu Lab X1C enable multiple filaments

- New curriculum possibilities (functional assemblies)

- Color coding for learning (anatomy, geology)

AI Integration:

- AI-assisted design tools for students

- Generative design exploration

- Automated optimization for printability

Sustainability Focus:

- Recycled filament programs

- Closed-loop material systems

- Design for sustainability curriculum

Expanded Materials:

- Flexible materials (TPU) for wearables

- Composite materials (carbon fiber, wood)

- Dissolvable supports (PVA) for complex designs

Cloud & Remote Learning:

- Remote print job submission

- Virtual printer monitoring

- Distance learning integration

- Global collaboration projects

📖 Related Historical Documentation

On This Site

- Skeinforge Documentation – Original slicing software used in BFB era

- G-Code Reference Guide – Understanding printer commands

- RapMan 3D Printer – The educational workhorse printer

- 3DTouch Printer – Consumer-friendly alternative

- Materials Catalog – Historical filament specifications

- Historical Archive Hub – Complete BFB documentation

External Resources

- The Guardian Video Archive – Clevedon School documentary

- EduTech Wiki – Academic research on early 3D printing education

- RepRap Wiki – Community technical documentation

- Archive.org – Wayback Machine snapshots of BFB resources

🎓 Academic Research

Key Papers on Early Educational 3D Printing

Recommended Reading:

- “The Impact of 3D Printing on Design Education” (2012)

- Documents early adoption in UK schools

- Cites BFB case studies

- Pedagogical frameworks

- “Maker Education: Revolution or Evolution?” (2014)

- Traces roots to RepRap and BFB

- Analyzes learning outcomes

- Longitudinal student tracking

- “From CAD to Reality: 3D Printing in STEM” (2015)

- Curriculum integration strategies

- Assessment methodologies

- Best practices compilation

💬 Contribute to This Archive

Help Us Preserve History

Do you have:

- Photos of BFB printers in your classroom (2008-2012)?

- Original lesson plans or curriculum materials?

- Student project examples from the BFB era?

- Teacher testimonials or experiences to share?

- Video footage of early 3D printing education?

Please contact us to contribute to this historical archive.

Your memories and materials help preserve this important chapter in educational technology history.

❓ Frequently Asked Questions

What 3D printers did Bits From Bytes use for education?

Bits From Bytes primarily recommended the RapMan 3.2 for educational use, both as a kit (£650-800) and pre-built (£1,200-1,400). The kit version allowed students to learn through assembly, while the pre-built option was ready for immediate classroom use. Later, the 3DTouch printer (£1,500-2,000) was introduced for younger students, featuring an enclosed design for improved safety and quieter operation.

How did schools integrate 3D printing into their curriculum?

Schools integrated 3D printing across multiple subjects, not just design & technology. In science, students printed molecular models and anatomical structures. In mathematics, they visualized 3D geometry and explored scaling concepts. In art, students created sculptures and relief printing plates. The most successful programs used project-based learning, where students designed solutions to real-world problems, like the e-NABLE prosthetic hand project featured at many BFB partner schools.

Is 3D printing still used in education today?

Yes, 3D printing is now more widespread in education than ever before. What started with pioneering schools like Clevedon in 2011 has become mainstream. Modern schools use printers from Prusa Research, Bambu Lab, and Ultimaker, benefiting from improved reliability, faster speeds, and lower costs. Today’s £300 printer outperforms the £1,500 printers from 2011, and comprehensive free curriculum resources are available from Prusa Education, MatterHackers, and other organizations.

What happened to Bits From Bytes educational programs?

Bits From Bytes was acquired by 3D Systems in 2010. Educational programs continued initially but were gradually phased out as 3D Systems consolidated product lines into their Cube series. However, the teaching methodologies and project-based learning approaches pioneered by BFB influenced the entire maker education movement. Many UK schools that started with BFB printers in 2009-2011 now have dedicated makerspaces with multiple printers.

What was the Guardian’s involvement with BFB education?

In 2011, The Guardian published a video documentary featuring Clevedon School’s innovative use of Bits From Bytes 3D printers. The coverage highlighted how 3D printing was transforming design & technology education, showcasing student projects and teacher testimonials. This mainstream media recognition helped legitimize 3D printing in education and inspired other schools to adopt the technology.

Can I still find BFB teaching resources?

The original BFB wiki is no longer online, but we’ve preserved and restored key teaching resources on this page, combining historical documentation with modern updates. For current teaching resources, we recommend Prusa Education (free lesson plans), MatterHackers Education, and the extensive project libraries on Thingiverse and Printables. The pedagogical approaches developed by BFB remain relevant and form the foundation of today’s maker education best practices.

What software did BFB schools use?

BFB schools primarily used Skeinforge for slicing STL files into G-code (see our complete Skeinforge documentation). For 3D design, schools used free software like Google SketchUp (beginner), Blender (advanced), and sometimes professional tools like SolidWorks with educational licenses. Today’s equivalent workflow uses Tinkercad or Fusion 360 for design, and PrusaSlicer or Cura for slicing – all more user-friendly than the 2009-2011 tools.

How much did it cost to set up 3D printing in a school?

In 2009-2011, a basic setup cost approximately £1,000-2,000 including:

- RapMan 3.2 printer (£650-1,400)

- Initial materials (£100-200)

- Software (mostly free/open source)

- Teacher training (often included)

Today, schools can start for £300-800 with significantly better equipment. A Prusa MINI+ at $349 (£300) or Creality Ender 3 V3 at £250 provides superior reliability and print quality compared to 2011 printers costing 4-5x more.

What safety considerations were important for BFB schools?

BFB emphasized several safety protocols:

- Heated component awareness (nozzles reached 200°C+)

- Proper ventilation for ABS printing

- Supervised operation at all times

- PLA preference over ABS (fewer fumes)

- No loose clothing near moving parts

Modern printers often include enclosed designs, automatic shut-off, and improved ventilation, making 3D printing even safer for educational environments. However, the fundamental safety principles established by BFB remain important.

How long did typical student projects take to print?

In the BFB era (2009-2011), print times were similar to today:

- Simple projects: 30 minutes – 2 hours (name tags, keychains)

- Intermediate projects: 2-6 hours (phone stands, mechanical parts)

- Advanced projects: 6-24+ hours (prosthetic hands, complex assemblies)

The challenge then (and now) was managing print queues with many students sharing one printer. BFB recommended after-hours printing with supervision, scheduling systems, and designing projects with realistic time constraints in mind.

🌟 Conclusion

Bits From Bytes recognized that 3D printing was more than a manufacturing technology – it was an educational revolution. Their teaching resources and school partnerships from 2008-2012 laid the groundwork for today’s ubiquitous maker education programs.

Their legacy lives on in:

- Thousands of students who got their first taste of digital fabrication

- Teachers who pioneered project-based learning with 3D printing

- Schools that built makerspaces and fab labs

- The open-source philosophy that continues to guide educational technology

Today, what BFB envisioned is reality:

- 3D printers in schools worldwide

- Integrated STEM curriculum

- Student-designed solutions to real problems

- A generation of makers and innovators

As we look forward, we honor those early pioneers who believed that every student deserves to be a creator, not just a consumer.

📞 Modern Educational Support

Get Started Today

Free Consultations:

Grants & Funding:

- DonorsChoose (US teachers)

- STEM Learning grants (UK)

- Local education foundation grants

- PTA/PTSA fundraising

Training Programs:

- Online courses (Coursera, edX)

- Maker educator bootcamps

- University certification programs

- Manufacturer training workshops

This historical documentation is provided for educational and archival purposes. The educational philosophies and methodologies pioneered by Bits From Bytes continue to inspire maker education worldwide.